What

is a "Command File"?

MillWrite is capable of reading a "command

file", which is a list of

instructions on what to do. This enables you to

use MillWrite on in an automatic or

semi-automatic mode.

If you download and install MillWrite,

(or this

version partially translated into German),

you can download and run this sample command file:

MillWrite-command-file,-cut-triangles-and-engrave.m8c

For two examples of how you can use

this feature:

1) Automatic CNC production

If you have software in your shop that is

creating part numbers, and if you need to engrave those part numbers,

then that software could create a MillWrite command file

that specifies the part number. The software would then call MillWrite

with that command file. MillWrite would follow the instructions in that

command file, and create a CNC program to engrave that particular part

number. This enables you to create CNC programs without any human

intervention.

2) Semi-Automatic CNC production

If you find that you are repeatedly doing the

same operations over and over, with only a few changes between them,

you could create a software program that asks you for the information

on how to make the particular part, or what to engrave on the part, and

after you have specified those parameters, your software creates a

command file for MillWrite.

Your

software could then call MillWrite to run that command file,

and MillWrite could either leave the job on the screen for you to

verify and/or modify, or it could create a CNC program for you.

For example, if you are repeatedly drilling some holes in

parts that you are making, but occasionally you have to modify the

quantity and/or placement of the holes, you would create a

software program that lets you specify the quantity and/or locations

for the holes, and after you have specified the information, your

software would create a command file for MillWrite that specifies those

particular holes to be drilled. This would be easier and more foolproof

than create a drilling program yourself for every part.

How to run a command

file

There

are several ways to run command files. Normally you would want to call

MillWrite from another software program. This method allows MillWrite

to be used automatically by other software.

If you are

creating your own software, you can call MillWrite from that software

with the name of the command file. For example, in the C language,

you would call it like this:

char MillWrite_8_folder[]

= "C:\\MillWrite_8\\"; //

folder that has MillWrite_8.exe

char MillWriteCommandFilename[200];

strcpy (MillWriteCommandFilename, "engrave text command file.m8c");

ShellExecute( NULL,

"open", // Operation to perform

"MillWrite_8.exe",

MillWriteCommandFilename,

MillWrite_8_folder,

SW_SHOW);

However, when you are designing and testing your command files, these

two methods are the most useful:

• Drag and drop a command file on top of the

MillWrite icon.

•

At the Drawing page, set one of the User-Defined Buttons to run

a command file. Then, when you click that button, it will ask you

to

select the command file, and when you do, it will run it for you.

If you want the help file for the User Buttons, download all of the

help files from this

page.

Command

files have three

possible outputs:

1) Create a CNC file that is saved on

the hard disk. MillWrite exits when finished.

2) Create a CNC file that is transmitted via serial port to

the CNC controller. MillWrite exits when finished.

3) Create a job file that remains on the computer screen

for you to deal with. MillWrite remains active so that you

can see the job file and decide what you want to do with it.

Command

files can modify

existing jobs or create new

jobs

1) Modify an existing job.

A command file can modify a job that you have

previously created and tested. This is useful when you want to do the

same job over and over, but each time you want to make some slight

change to it. For example, you might want to engrave a particular part

over and over, but each time you need to change one or move of the text

items, but you do not want to change any of the text locations, tool

feed rates, or anything else. In that case, you would use the "open

job=" command to open that particular job, and then modify only the

items that you want to change.

This is the easiest and most foolproof way of using a command file

because you can test the job ahead of time to make sure that you have

set everything correctly in regards to the tool's feed rate, the text

height, the tools' cutting depth, etc..

Your CNC program will be perfect when you make subtle changes to a job

that you have already proven to work correctly.

2) Create a new job.

A command file can create polylines, text to

engrave, data matrix barcodes, and other items, so you could create

whatever you need. MillWrite will give each new item whatever defaults

you have set in MillWrite, and you can override any of those defaults

with the command file, if you need to.

If your default feed rate, tool number, text type, and other parameters

have been set appropriately, then this is an easy way to create

programs to engrave some tax, or to cut a logo.

Structure of the command file

• The command file is a plain text

file

that lists the commands one after the other.

• The commands are processed

in the order that they are listed, just like a human follows a list of

instructions.

• The commands can use upper and/or lower case.

• There are two types of commands:

1) Commands that have

an equal sign.

These commands set a value. The value

follows

the equal sign. For example, the following command will set the radius

to 1.34 units:

radius=

1.34

The following command will open the job with the filename of "Engrave

serial number.job"

open job= Engrave serial number

2) Commands without

equal signs.

These commands do something, but they don't

set values. For example, the following command duplicates the texture

geometry that is active:

duplicate

• Use ASCII 135 to separate lines of text, ie, ‡

The phrase "ASCII 135" represents the ASCII

character #135, which is one of the characters that people used to make

footnotes. It looks like this: ‡

Each command has to fit on one line. As with a typical CNC program, the

invisible carriage return and linefeed characters are used to separate

the commands from one another. If you want to engrave a paragraph, all

of the text has to be on one line, and the way to do that is to

separate each block of text in the paragraph with the ASCII character

135 to show MillWrite where a block of text ends. For example, to

engrave these three lines:

Part 5501-a

SN: 123

Made in USA

Put that footnote character at the end of each line like this:

engrave=

Part 5501-a‡SN: 123‡Made in USA

You don't need to put a footnote character at the very end of the

text.

The list of commands

Here are the commands that MillWrite has right

now.

• *

The * is a comment for yourself, MillWrite ignores it

Don't put a comment on a line that has text or MillWrite will assume

it's part of the text.

It is best to put

the comment on a line by itself.

• countersink depth=

• countersink num=

• duplicate

•

engrave=

use ASCII 135 to

identify the end of each line of text

• feed=

• line length=

•

polyline

followed by x, and y values, and optional z, values

• machining batch=

• machining order=

• max depth per cut=

• move to xy=

• open job=

• radius=

• replace

text=

use ASCII 135 to identify the end of each line of text

• rotate=

• scale xyz=

• speed=

• surface

radius=

the radius of the cyclinder , which may be on a 4th axis

• surface

z=

• tap depth=

• tap num=

• text

align=

• text angle=

• text height=

• text length=

• text height and length=

• tool depth=

• tool diameter=

• tool num=

• tool z surface=

• use

item=

followed by the text name of the item

to activate

• work

offset=

eg, G54, G55, etc

• x=

• y=

• edit group

for editing a

"grouping"

• finished with group

• save cnc=

• transmit cnc=

• apply tool table

• disable 4th

• read tool text

file=

ie, get tools from tool list.txt

• remove unused

•

reorder

reorder machining order to reduce rapid

moves

• make

datamatrix=

creates a Data Matrix barcode

• cell size=

only for Data Matrix barcodes

Concepts behind the command file

Some commands need to be placed in a certain

order in order for them to work properly, but some commands can be

placed anywhere because they are merely instructions to MillWrite. For

example, the command to save the CNC file ("save cnc=") can be placed

anywhere because it is simply telling MillWrite that you want the CNC

program saved on disk. Example:

save cnc= c:\NC Programs\engrave part number.cnc

That command does not modify anything, so it doesn't matter where in

the command file you tell MillWrite that you want the CNC program saved.

However, some commands modify geometry or text, and that requires that

they be placed after the text or geometry has been made "active". If

you are creating new text and geometry, an item becomes active as soon

as you create it, and it remains active until you create some other

item.

For example, the command to create some text is "engrave=". After the

text has been created, you can use any of the text or tool modification

commands to adjust that text. It doesn't matter what order those other

commands are in because all of them operate on the active tax. Both of

the following sets of commands will do exactly the same thing:

engrave= Part # 12-44

revB this creates the text and

makes it active

text height=

.25

it doesn't matter what order these other commands are in,

tool depth=

0.034

as long as they are after the "engrave=" command

tool num= 4

engrave= Part # 12-44 revB

tool depth= 0.034

tool num= 4

text height= .25

Need a Command that does not yet exist?

MillWrite has the ability to process the

commands that

people have requested, but there are hundreds of possible commands that

MillWrite could process. Therefore, if you need a particular feature,

add for it, and it will be add it to command list, assuming it is

practical to do so.

A description of the commands

Note that after the

= you can put one or more blank spaces to make

it easier to read.

• open job=

This command will open a

job and allow you to make modifications to it. Although it should be

obvious, this should be one of the very first commands in the command

file because in order to modify an existing job, you must first open it.

• You do not need to include

the extension ".job".

• If you do not include a

drive and folder, MillWrite will use whatever drive and folder that you

specified to be the default folder for for job

files (you set that at the Setup page).

• use item=

You need to use this command when you want to open

an existing job and modify one of the items within it.

A

text item is identified by its text, and rectangles, polylines, and

other items are identified by the "name" that you have given the item.

In case you have not noticed, most of the items that you create have a

"name" data field that is you have probably left blank. If you want to

modify any of those items with a command file, you must give that item

a unique name.

For an example of how to use this command, assume

you created a job file that engraves a part number, serial number, and

recycling symbol, and assume that you want to change the serial number

each time. In that case, you might set up the serial number as "serial

number", or as "replace this text". You could modify that serial number

simply by making it active with the following command:

use item= serial number

replace text= SN 0034-3

Or:

use item= replace this text

replace text= SN 0034-3

Note:

you don't have to specify the complete text, or the complete name, of

the item. You only have to enter as much text as is unique. For

example, assume you have these two lines of text in your job

file:

replace

this text to engrave part number

replace this text for

serial number

You can make the first text item active with any of the following four

commands:

use

item= replace this text to engrave part number

use item= replace this text to engrave part

use item= replace this text to engrave

use item= replace this text to

And you can make the second text item active with any of these three

commands:

use

item= replace this text for serial number

use item= replace this text for serial

use item= replace this text for

• replace text=

Normally

you use this command to replace the text that you want to engrave. It

will also change the name of a polyline, rectangle, or other item, if

you want to do something more complicated (an example of a more

complicated use will be mentioned farther down in this document).

Note:

each command can be only one line long. Therefore, if you want to

replace a text item with multiple lines of text, you need to separate

each line of text with an ASCII 135 character to let MillWrite

know that each

where to put the line breaks. For example, assume that you want to

replace the text to engrave with the following paragraph:

Do not put in dishwasher.

Do not immerse.

Part number 355-3

Made in USA.

Use the ASCII character 135 to separate the lines, like this:

replace

text= Do not put in dishwasher.‡Do not immerse.‡Part number 355-3‡Made

in USA.

• x=

This will change only the X coordinate of the

active item. Example:

x=

3.456

• y=

This will change only the Y coordinate of the

active item.

• move to xy=

This

will set both the X and Y coordinates of the active item with just one

commmand. Separate the X and Y values with a comma, tab, or a blank

space. Example:

move

to xy= 3.456, -7.654

• text height=

This will set the height of the active text.

See the blue

note below.

• text length=

This will set the length of the active text.

See the blue

note below.

• text height and length=

This

will set both the height and length of the text and adjust the width

ratio so that the text fits that particular height and

length.

Note about setting

the text height and length:

Text

has a height, length, and with ratio. You can set only two of those

three parameters because the third is calculated from the other two.

If

you are creating new text, it will be given a width ratio of 1.0. If

you set the height of the text, the length will be adjusted in order to

keep the width ratio at 1.0. If you set the length, then the height

will be adjusted. If you want to set both height and length, then use

the "text height and length= command.

However, if you are

modifying a text item in an existing job file, and if the existing text

already has a width ratio other than 1.0, then if you use the "text

height= or "text length= commands, MillWrite will assume that you are

trying to force the text to be a certain height and length, and so it

will allow the width ratio to change.

To summarize this, when

you create a job file that you plan to modify with a command list, and

when you want to modify the text items in that job file, set their

width ratio to 1.0 if you want the width ratio to remain 1.0 after you

have modified them. If you modify a text item that has a width ratio

other than 1.0, MillWrite will assume you are trying to force the text

to fit a certain whatever height and length that you designed for that

particular text item.

If you want the text to fit a certain

height and length, The best option would probably be to use

the command: "text

height and length="

• text angle=

This

will set the rotation angle of the text. Enter a value in degrees. The

3 o'clock position is at 0°, and the 12 o'clock position is at 90°.

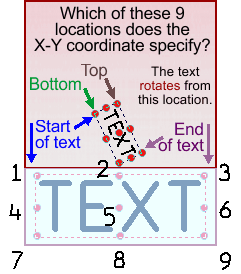

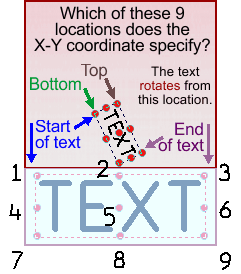

• text align=

If

you want to set the alignment for the text, specify a value from 1 to

9. MillWrite offers nine alignment points for text. The XY coordinates

of the text refer to the alignment point. For example, the following

commands set the upper left corner of the text to be at a coordinate of

4.5, 7.3:

use item= replace this text

replace text= Part #: 56900 -rev2

text height= .25

text align= 1

move to xy= 4.5, 7.3

• feed=

This will set the feed rate of the tool for the

active item.

• speed=

This will set the speed of the tool in RPM for

the active item.

• tool depth=

This

specifies the depth for the tool for the active item. The value is

always positive. For example, the following command will set the tool

to a depth of 0.5 units below whatever the surface is.

tool depth= 0.5

• tool diameter=

This sets the tool diameter of the active item.

When

you are engraving geometry, you do not need to specify the tool

diameter because it has no effect on the CNC program. However, when you

are contouring or pocketing geometry, the tool diameter is critical.

Also, when MillWrite engraves text, it separates the characters by the

width of the tool so that they don't cut into one another.

• tool num=

This will specify the tool number for the

active item. This will become the "T" number in the CNC program.

• tool z surface=

This

sets the Z coordinate at which the tool would touch the surface for the

active geometry. It sets the data field that MillWrite refers to as "Z

Surface"

• max depth per cut=

This will set the max depth per cut of the tool

for the active item.

• machining batch=

This will set the machining batch of the active

item.

• machining order=

This will set the machining order of the active

item.

• duplicate

This

command will duplicate, that is, make a copy, of whatever item is

active. This command is useful when you need to engrave or cut several,

nearly-identical items. You only have to create one item, and then you

can duplicate that one item, and make changes to it.

For

example, assume you need to engrave text at various openings on a mold.

Some molds have to be engraved at five different locations, and others

have to be engraved at six locations, and others need to be engraved at

eight locations. You could create a job file for every possible

situation, but if you have dozens of possible situations, that would be

a lot of work.

It would be easier to create just one text file

with just one text item. You would then activate that one text item,

put it into the proper XY location, and then duplicate it for the

second location. You would then change its XY coordinates, its text,

and whatever else is necessary, and then you could duplicate it again.

The

following set of commands will modify the text item that is called

"replace this text". It will change that text to "Main Power", and then

duplicate that item. The duplicate item will be moved to an XY

coordinate of 1.23, 4.5, and the text will be replaced with ON/OFF.

Then that text item will be duplicated, and the x-coordinate will

remain what it already is, but the Y will be changed to 7.44, and the

text will be replaced with "Fuel Level".

use

item= replace this text

replace text= Main Power

duplicate

replace text= ON/OFF

move to xy= 1.23, 4.5

duplicate

y= 7.44

replace text= Fuel Level

• rotate=

This

will rotate the active item by whatever degrees number of degrees you

specify. The rotation is anti-clockwise if the value is positive, and

clockwise if you enter a negative value. For example, the following

command will rotate the item by 20° anti-clockwise.

rotate=

20

When

engraving text, you do not need to use this command. Text has a special

command, "text angle=, which lets you specify the rotation angle of the

text.

• scale xyz=

This will scale the active item by the X, Y,

and Z values that you specify.

When

you are engraving text, you normally will not want to use the scale

command because you can more easily control the size of the text by

setting the text height, and/or the text length. However, when the text

is wrapped around a circular arc, or following a polyline, you might

want to use the scale command.

Normally you will not want to

scale in the Z axis, so you mormally would enter only one or two

values, or specify a Z scaling factor of zero. If the scaling factor in

Y is the same as in X, which is usually what you want to do, then you

only need to enter one value. For example, the following command will

scale the active item by a factor of three.

scale xyz= 3

That is equivalent to this command:

scale xyz= 3, 3, 0

If

you specify an X scaling factor that is different from the Y scaling

factor, then the item will be stretched or compressed. For example, the

following command will stretch the item 3 times in the x-axis, but only

two times in the Y axis.

scale xyz= 3, 2

If

you wonder why somebody would want to scale an item differently in X

and Y, one purpose is to make rectangles. For example, you could create

a job file that has a square that is one unit in size. Then, whenever

you want to cut a rectangle, the scaling factor becomes the size of the

rectangle. For example, if you want to cut a rectangle that is 5 units

in X and 7.6 units in Y, you would enter:

use item= 1 unit square

move to xy= 1.23, 4.5

scale xyz= 5, 7.6

If

you are scaling a circle, the scaling occurs from the center of the

circle. If you are scaling something else, it occurs from wherever the

start node is. Likewise, when you use the "move to xy= command, if you

are moving a circle, it moves from its center, otherwise it moves from

its start node.

• engrave=

If you want to create

a new text item, rather than use some existing text, then use this

command. As with the "replace= command, if you want to create a text

item with multiple lines, separate them with ASCII 135. For example,

the following command creates one text item with two lines of text:

engrave= This is new text.‡And this is the 2nd line.

• polyline

If

you want to create a polyline, use this command, and follow it with a

set of XYZ coordinates. This is the only command that does not follow

the rule that each command is on its own line. In this case, the

command polyline is on its own line, but underneath it are sets of

coordinates, one for each node of the polyline. For example, the

following command list will create a triangle:

polyline

0,0

6,0

3,5

0,0

The

start node of the polyline is the first XY coordinate, which in this

case is 0,0. If you do not specify Z values, they will be set to zero.

This command can be useful if you need to engrave some lines,

arrowheads, or other shapes.

If you specify Z values, you will create a 3D polyline, which will

enable you to cut 3-D shapes.

After you create a polyline, you can duplicate it, move it, scale it,

or rotate it.

• line length=

A

polyline can be a long chain of lines, arcs, and splines. If you create

a polyline that is

just one, single line, then you can use

the "line

length= command to set the length of that line. For example, you could

create a horizontal line in a drawing, and refer to it as "horizontal

line". Your command file could then set it to whatever length you want,

and move it into whatever XY location you please. For example, the

following command list will set it to a length of 5.6 units, and move

it to 1.23, 4.5.

use item= horizontal line

move to xy= 1.23, 4.5

line length=5.6

• radius=

This

sets the radius of a point or circle. If you are going to create CNC

code, you do not need to set the radius of a point. However, if you are

using the command file to create a job file that remains on the

computer screen, then you might to give the points the radius of the

drill so that you can by see their size.

use item= contoured circle

move to xy= 1.23, 4.5

radius=6.9

• surface radius=

When you are cutting a cylinder on a 4th axis,

or a cylinder that is clamped into a vise, this sets the radius of that

cylinder.

• surface z=

When

specifying a cylinder, or other three-dimensional shape, which you

normally do at the SETUP page, this is the Z coordinate at which the

tool would touch the top of the 3-D shape.

Note: do not get

command this mixed up with the "tool Z surface=. The "Surface z=

command defines the block of material that you are cutting, which

affects the entire job, whereas "tool Z surface= sets the tool for only

one piece of geometry.

There will be only one "surface z=

commands in a command file, but there may be as many "tool Z surface=

commands as there are items to cut.

• make datamatrix=

If you want to cut a data matrix barcode, this

command sets the data for the barcode.

Examples:

1) To cut a data matrix barcode that contains the

data "Part # 123786", do this:

make datamatrix=

Part # 123786

2) To cut a data matrix barcode that contains

these 3 lines of data:

Part

# 123786"

SN 43304-1"

Made in USA"

Use the footnote character ASCII 135

(‡) to show where you want a line break, like this:

make datamatrix= Part # 123786‡SN 43304-1‡Made in USA

• cell size=

This

command is valid only if you have made a data

matrix barcode active,

either by creating it with "make datamatrix=, or by selecting one from

an existing job. This sets the distance between the cells of the

barcode.

• read tool text file=

If

you have used MillWrite to create a plain text file of your tools, this

command will read one of those lists into the tool table.

For example, this will set your tools to whatever is in the file

"Engrave brass tools.txt"

read tool text file= Engrave brass tools.txt

To

create a plain text file of your tools, switch to the Setup page of

MillWrite, and then click your RIGHT mouse button over the tool list

button. A menu will appear, and one of the options is to Write The Tool

List To A Text File. If you use that feature, you can save one or more

tool lists, and you can modify them, also. The "read tool text file=

command will read whichever of those tool lists you specify after the

equal sign.

• apply tool table

This command will apply your default tool table

to the items in the drawing.

Be

careful about where you place the "apply tool table" command in the

command file. That command applies the tool table immediately, so it

affects only the items that have already been created, not the items

that are created after this command.

If you use the "open job=

command to modify an existing job file, then it would be useless to put

the "apply tool table" before the "open job= command. Instead, place it

afterwards so that after the job has been opened, the tool table is

applied to everything in the job. You can then use the command file to

modify whatever tool settings you want to change.

For example,

the following commands will open an existing job called Engrave part

number, and the next command will read Engrave brass tools.txt to

create a tool list, and then that tool list will be applied to

everything in the job. After the tool table has been applied, the tool

depth for the engraved text called "replace this text" is overridden

with a new value.

open

job= Engrave part number

read tool text file= Engrave brass tools.txt

apply tool table

use item= replace this text

tool depth= 0.034

replace text= Part #: 56900 -rev2

text height= .25

text align= 1

move to xy= 4.5, 7.3

If

you put the "apply tool table" command at the end of the command list,

then you can ensure that all of the items in the drawing have those

default tools settings.

If you are creating a new job there is

no sense in putting this command at the beginning of the command list

because there will be nothing in the job file yet. In that case, you

would put it at the end of the command list so that it sets everything

that you create to the default tool settings.

The following commands can be placed anywhere in the

command file because they affect the entire job, not any individual

item:

• reorder

This command tells MillWrite to set the cutting

order of the items in the job to reduce rapid moves.

• remove unused

This

command has an effect only when you are modifying an existing job. It

does nothing when the command file is creating a new job.

When

you modify an existing job file, there might be some situations in

which you do not want all of the text in that job file to be engraved,

or you do not want all of the drilling points to be drilled, or you do

not want all of the geometry to be contoured, etc.. Rather than delete

the items that you do not want to use, you can use this command, and it

will delete everything that you have not made active.

For

example, assume you have a job file that has a line of text to engrave,

a logo to engrave, and a drilling point. The following command list

will engrave the text, but delete the logo and the drilling point:

save cnc= 1000.EIA

remove unused

open job= Engrave serial number

use item= replace this text

replace text= SN 0034-3

If you want to use the drilling point, then you

have to make it active, even if you don't do anything to modify it. For

example:

save cnc= 1000.EIA

remove unused

open job= Engrave serial number

use item= replace this text

replace text= SN 0034-3

use item= drill hole

• transmit cnc=

If

you specify this command, instead of saving the CNC program on disk,

MillWrite will transmit the CNC program through the serial port to the

CNC machine. This command is useful only when your computer is

connected to the CNC machine through a serial port, and the machine is

ready to receive.

MillWrite will use whatever serial port

protocol you have specified in this command. For example, if you have

two serial port protocols, one of them is referred to as "Centroid on

COM1", then the following command will use that serial port

specification to transmit the file:

transmit cnc= Centroid on COM1

• work offset=

If

you want to specify the work offset number, and G54 to G59, enter the

value in this command. For example, if you want G56, use this command:

work offset= 56

Note

that you will not get the G54 to G59 command in the CNC program unless

you specified that the postprocessor include a work offset number. To

do that, you need to put a "W#" in the Starting Code block and/or the

Tool Change block, of the postprocessor.

• disable 4th

When using a 4th axis, this command will cut

whatever is

the active item by holding the 4th axis motionless, rather than by

rotating the 4th axis.

This is the same as checking the box that

says "Disable 4th axis for this item", which you find at the bottom of

the Tool tab, it the data field called "More options".

|